Bio leather, or bio-based leather, is a leather substitute material produced through biotechnology rather than conventional animal husbandry or purely petrochemical synthesis. Its core characteristics stem from its biological origins and environmental sustainability.

As an innovative leather alternative, bio-leather closely resembles conventional leather in appearance and texture. Its durability, strength, and weight are comparable to traditional leather, making it suitable for diverse applications such as manufacturing bags, footwear, and fashion accessories.

This article explores the definition and classification of bio-leather, its waterproof and durable properties, and the advantages and disadvantages of using bio-leather for bag production.

- What is Bio Leather?

- Performance Characteristics of Bio-Leather

- What is Bio-Leather Made From?

- Primary Raw Material Classifications for Bio-Leather

- Manufacturing Techniques for Bio-Leather

- Is Bio-Leather Environmentally Friendly?

- Applications of Bio-Leather

- Challenges and Controversies Surrounding Bio-Leather

- How Bio Leather Compares to Other Leathers

- The Future of Bio-Leather

- Is Bio Leather Real Leather?

- How to Make Bio Leather?

- I. Plant Fiber-based Bio-leather (Taking pineapple leaf Fiber as an Example

- Ii. Mycelium-based Bio-leather (Taking Mylo as an Example)

- Iii. Collagen-based Bio-leather (Taking VitroLabs Technology as an Example)

- Iv. Biopolymer-based Bio-leather (Taking PLA as an Example)

- V. Innovative Process: Fungal Fruiting Body Recombination Method

- Is Bio Leather Durable?

- Is Bio Leather Vegan?

- Is Bio Leather Waterproof?

- Is Bio Leather Good for Making Bags?

- Conclusion

What is Bio Leather?

Bio leather, also known as bio-based synthetic leather, constitutes a broad category of vegan leather crafted from renewable biological materials. It serves as a sustainable alternative to conventional leather, utilising biological processes such as fermentation or tissue engineering rather than animal hides or purely synthetic chemicals (e.g., PU/PVC).

The core characteristics of bio leather lie in its reliance on bio-based raw materials (plant matter, microorganisms, or cell cultures) to mimic the desirable properties of animal leather. It minimises environmental harm during production, addresses ethical concerns, and aligns with circular economy principles.

Unlike conventional leather (animal-derived) or synthetic leather (fossil fuel-derived), bio-leather unites performance, ethics and sustainability, establishing it as a cornerstone for eco-conscious fashion, accessories and industrial design.

Performance Characteristics of Bio-Leather

- Environmental Sustainability: Bio-based leather significantly reduces carbon footprints, aligning with global green consumption trends. Its renewable raw materials and production processes decrease reliance on petroleum-based resources, mitigating resource depletion and environmental pollution.

- Ethical Advantages: Bio-based leather eliminates the use of animal hides, bypassing the slaughter inherent in traditional leather production and addressing consumer concerns regarding animal welfare.

- Controllable Properties: By adjusting production techniques and raw material ratios, the hardness, elasticity, breathability, and other properties of bio-based leather can be precisely controlled to meet diverse application requirements.

- Appearance and Texture: Bio-based leather can replicate the look and feel of traditional leather, and in certain aspects (such as uniformity and consistency) even surpasses it.

What is Bio-Leather Made From?

Bio-leather is typically produced using natural or bio-based sources, such as:

- Plant fibres (pineapple leaves, cactus, apple peel, grape skin)

- Mycelium (fungal roots)

- Natural rubber

- Corn or sugarcane-based polymers

- Bacterial cellulose

Some bio-leathers are entirely bio-based, while others are blends combining plant materials with small amounts of synthetic binders to enhance durability.

Primary Raw Material Classifications for Bio-Leather

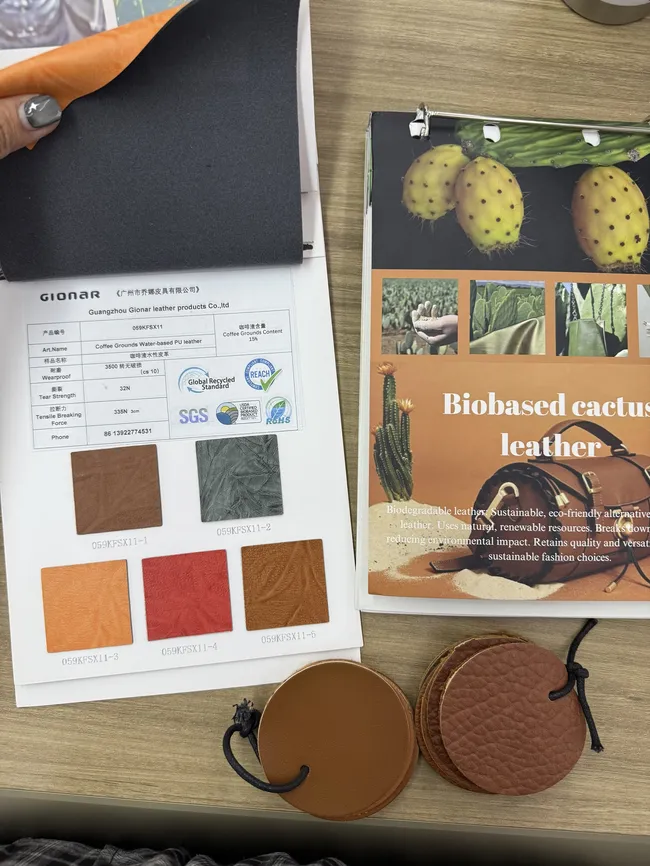

- Plant-based materials: e.g., pineapple leaves (Pinatex), apple peel, citrus fruits, corn starch, and cactus.

- Microbial sources: including mycelium (fungal roots), bacteria, and yeast.

- Other biological resources: such as coffee grounds, algae, and even food waste.

Production processes vary by raw material but typically involve microbial fermentation, enzymatic treatment, and bioprocessing of natural fibres to create leather-like materials.

Manufacturing Techniques for Bio-Leather

Is Bio-Leather Environmentally Friendly?

Bio-leather is generally considered more sustainable than animal leather because it:

- Reduces reliance on livestock

- Uses fewer toxic chemicals

- Has a lower carbon footprint

However, not all bio-leather is 100% biodegradable – some still contain PU or other synthetic coatings, so sustainability depends on the specific material.

Applications of Bio-Leather

- Fashion Industry: Bio-based leather has become a favourite in the fashion sector, widely used in apparel, footwear, and luggage. Its unique eco-friendly properties and stylish appearance have attracted significant attention from designers and consumers.

- Automotive Interiors: As the automotive industry increasingly prioritises environmental protection and sustainability, bio-based leather is progressively being adopted for interior components such as car seats and steering wheels.

- Electronics: Certain premium electronic devices (such as mobile phone cases and tablet covers) now incorporate bio-based leather as an exterior material to enhance their eco-friendly image and user experience.

- Other Sectors: Bio-based leather also finds applications in furniture and decorative items, offering an environmentally conscious alternative to traditional leather goods.

Challenges and Controversies Surrounding Bio-Leather

- Bio-based Content Concerns: Many bio-based leather products contain only partially bio-derived raw materials, with coatings, adhesives, and other components potentially still containing petroleum-based elements. This has led to questions regarding the environmental credentials of certain products.

- Degradation Performance: Bio-based polyurethane (PU) shares similar chemical structures with petroleum-based PU, resulting in slow degradation in natural environments. Only a few pure bio-based materials (e.g., uncoated pure mycelium mats, pure plant fibres) readily decompose in home composting.

- Production Energy Consumption and Chemical Usage: Manufacturing processes such as fermentation, polymerisation, and coating still require energy and may involve chemical usage. This increases production costs and environmental impacts for bio-based leather.

- Lack of Standardisation and Certification: The absence of unified environmental certification standards (e.g., degradation criteria, carbon footprint accounting) leads to market confusion and “greenwashing” controversies. Consumers often conflate the “bio-based” concept with synthetic leather.

How Bio Leather Compares to Other Leathers

| Aspect | Bio Leather | Traditional Animal Leather | Synthetic Leather (PU/PVC) |

| Raw Material | Renewable bio-based feedstocks | Animal hides | Petroleum (non-renewable) |

| Environmental Impact | Low (circular, low CO₂/water use) | High (polluting tanning, deforestation) | Medium (fossil fuels, microplastics) |

| Biodegradability | Yes (1–5 years) | Yes (5–10 years, if vegetable-tanned) | No (persists 50+ years) |

| Durability | 3–10+ years (varies by type) | 10+ years (premium full-grain) | 2–5 years (prone to cracking) |

| Cost | Mid-range (higher than PU, lower than premium leather) | High (especially full-grain) | Low |

| Ethics | Cruelty-free, non-toxic | Animal exploitation, toxic tanning | Cruelty-free, but toxic production |

The Future of Bio-Leather

Driven by sustainable fashion and industrial material demands, bio-leather is rapidly advancing:

- Scalability: Companies like Bolt Threads (Mylo) and Modern Meadow are expanding production to reduce costs and compete with synthetic leather.

- Innovation: New raw materials—such as algae, coffee grounds, and even food waste—are being tested to further enhance circularity.

- Performance: Advances in bio-based coatings and polymer blends enhance water resistance, durability, and scratch resistance.

As consumers and brands prioritise sustainability, bio-based leather is poised to replace a significant portion of traditional and synthetic leather—particularly in fashion, automotive, and homewares.

Is Bio Leather Real Leather?

No, bio leather is not genuine leather in the traditional sense. It is a leather alternative produced from renewable biomass resources via biochemical or bioengineering processes, designed to mimic the appearance, feel, and performance of conventional leather while meeting environmental and ethical consumption demands.

Therefore, bio-leather is not ‘genuine’ or ‘real’ leather. Whilst sharing similar appearance, feel, and applications, it fundamentally differs in biological origin and production methods.

Core definitions of ‘genuine leather’ (traditional vs. contemporary)

Traditional definition

‘Genuine leather’ (or ‘full-grain leather’) is legally and culturally defined as material derived from animal hides (such as cattle, sheep, goats) that undergoes tanning to preserve its structure. The key requirement here is animal origin – the material must be sourced from intact animal skin, processed into a supple yet durable textile. By this standard, most bio-leathers do not qualify as genuine leather.

Modern/Functional definition

Some experts and consumers define ‘genuine leather’ based on structure and performance rather than origin: materials that mimic or match traditional leather’s collagen structure, suppleness, and durability. Under this criterion, lab-grown bio-leather qualifies as genuine leather, while plant-based and microbial bio-leathers remain ‘leather alternatives’.

Why bio-based leather isn’t ‘genuine’ leather?

Bio-based leather differs fundamentally from genuine leather:

- Source: Genuine leather must originate from animal hides, whereas bio-based leather primarily derives from plants or microorganisms.

- Structural differences: Genuine leather possesses a natural three-dimensional fibrous network and irregular pores, while bio-based leather features artificially simulated structures.

- Certification standards: International certifications for ‘genuine leather’ (e.g., LWG certification) mandate animal-derived hides; bio-based leather fails to meet this criterion.

It is noteworthy that certain bio-based leather products (such as vegetable-tanned leather) fall within the genuine leather category, as they still utilise animal hides as raw material, albeit through more environmentally friendly tanning processes. The true point of confusion arises when ‘bio-based synthetic leather’ is also abbreviated as ‘bio-based leather’ in the marketplace, leading to consumer misunderstanding.

Genuine leather vs. Bio leather: A clear distinction

| Feature | Genuine (Animal) Leather | Bio Leather (Biofabricated) |

| Source | The processed hide or skin of an animal (e.g., cow, sheep). | Grown from living organisms like fungal mycelium (mushroom roots) or bacteria. |

| Core Material | Primarily collagen, a natural protein from animal connective tissue. | Primarily chitin (from fungi), cellulose (from bacteria/plants), or other biopolymers. |

| Production | A “tanning” process that preserves and treats animal skin. | A “fabrication” or “fermentation” process that grows a material from scratch. |

| Key Point | It is a byproduct of the meat industry. | It is intentionally grown in labs or bioreactors without animals. |

How is bio leather different from real leather?

| Aspect | Bio Leather | Traditional Leather |

| Source | Plants, fungi, bio-polymers | Animal hides |

| Sustainability | Lower environmental impact | High water & chemical use |

| Animal use | Animal-free | Animal-derived |

| Texture | Can mimic leather | Naturally leather |

| Biodegradability | Often partially biodegradable | Not biodegradable |

Why is there confusion?

The term “leather” is used to describe the functionality and aesthetic appeal of the material – its durability, flexibility and texture – rather than its biological origin. This is a category name, just as “plant milk” describes a function (a milk-like beverage), rather than an animal source. Here are some reasons for the confusion:

- Marketing language: Some brands use terms like “genuine bio-leather” to emphasize durability, but this is misleading – regulatory authorities and industry groups reject such labels.

- Technological progress: Laboratory-grown bio-leather is very similar to genuine leather in composition and performance, challenging the traditional definition. As the production scale expands, regulatory authorities may update the definition to include it.

- Consumer demand: Environmentally conscious consumers often prioritize sustainability over “genuine leather” labels, making bio-leather a popular choice regardless of classification.

Genuine leather is an animal product. Bio-leather is an engineered biological material. They are different categories. Bio-leather offers a sustainable and cruelty-free alternative that mimics the ideal quality of traditional leather.

How to Make Bio Leather?

The production of bio-leather is not a single formula but a collection of a series of advanced biotechnological processes that can grow or assemble materials at the microscopic level.

The production of bio-leather varies depending on the raw materials (plants, microorganisms or cells), but the core principles are the same: using renewable biological resources, minimizing toxic chemicals, and prioritizing recyclability. The following are the detailed steps and explanations of the mainstream processes.

I. Plant Fiber-based Bio-leather (Taking pineapple leaf Fiber as an Example

Core raw materials: Pineapple leaves, corn-based PLA (polylactic acid), bio-based polyurethane (Bio-PU)

Process flow

Fiber extraction

Collect the discarded leaves of pineapples after picking and remove the long fibers by mechanical or semi-mechanical means.

Clean to remove impurities and set aside naturally or by drying.

Substrate preparation

Web formation: Fluffy and comb the fibers to form a net-like structure.

Reinforcement: Mixed with corn-based PLA, the fiber entanglement is enhanced through needling or spunlacing processes to form a non-woven fabric substrate.

Coating treatment

Multi-layer coating with bio-based PU endows water resistance, durability and a specific hand feel.

Post-organization

Embossing (creating granular patterns), dyeing, printing, polishing, etc., endow the final appearance and touch.

Advantages: Renewable raw materials, low cost; The technology is mature and suitable for large-scale production.

Challenges: Relying on adhesives (partially containing PU), fully bio-based formulas have not yet been widely adopted.

Ii. Mycelium-based Bio-leather (Taking Mylo as an Example)

Core raw materials: Mushroom mycelium, agricultural waste (sawdust, straw)

Process flow

Strain culture

Cultivate specific mushroom mycelium (root structure) in the laboratory.

Growth process

Mix the strain with the pre-treated agricultural waste and place it in a shallow tray for solid-state fermentation.

After growing for 2 to 3 weeks, the mycelium forms a foam cushion-like structure, integrating the matrix network into one.

Harvesting and Processing

Harvest before the mycelium matures, kill the mycelium through heat treatment and stop its growth.

After cleaning and drying, the density and thickness are increased through hot pressing, and a leather-like texture is formed on the surface.

Tanning and finishing

It is made softer and more durable by using plant tanning or chromium-free chemical tanning processes.

Dyeing and surface coating (usually bio-based PU) to achieve the desired performance and appearance.

Advantages: Short cycle (about 2 weeks), low resource consumption; The tensile strength exceeds that of traditional leather, and the weight is reduced by 30%.

Challenge: High equipment investment, with costs approximately 2 to 3 times that of traditional leather.

Iii. Collagen-based Bio-leather (Taking VitroLabs Technology as an Example)

Core raw materials: Animal stem cells (such as bovine cells), bioreactors

Process flow

Cell extraction and culture

Animal stem cells are extracted and proliferated and differentiated in a bioreactor to form a collagen layer.

Construction of layered structure

By regulating the culture conditions, the microstructure of traditional leather (such as fiber arrangement) is simulated.

Post-processing

Tanning, dyeing and surface treatment endow the final performance.

Advantages: No need to slaughter animals, and the microstructure of traditional leather is retained.

Challenge: The technology is still in the laboratory stage, with extremely high costs and has not yet been commercialized.

Iv. Biopolymer-based Bio-leather (Taking PLA as an Example)

Core raw materials: polylactic acid (PLA, extracted from corn), environmentally friendly plasticizers

Process flow

Raw material preparation and mixing

Mix PLA particles with environmentally friendly plasticizers, pigments and additives in proportion and stir at high temperature to form a liquid slurry.

Coating or impregnation

Coating method: Use a precision scraper to evenly apply the slurry onto the surface of the base fabric (such as recycled polyester).

Impregnation method: Fully immerse the base fabric in the slurry, extrude the excess slurry and then cure it.

Gelation and curing

The coated material enters the oven. After the slurry gels, it firmly adheres to the base fabric, forming a leather blank.

Surface treatment

Embossing, printing and coloring are carried out to endow a specific touch and gloss.

Advantages: Renewable raw materials and environmentally friendly process; Suitable for high-performance scenarios such as automotive interiors.

Challenge: High cost, large-scale production is needed to reduce costs.

V. Innovative Process: Fungal Fruiting Body Recombination Method

Core raw materials: Fungal fruiting bodies, modified cellulose short fibers, waterborne polyurethane

Process flow

Treatment of fungal fruiting bodies

Crush the fruiting bodies and carry out surface grafting modification in an aqueous medium.

Slurry preparation

Mix with modified cellulose short fibers and anti-settling agents, add waterborne polyurethane, plasticizers, pore-forming agents and crosslinking agents, and stir evenly.

Forming and drying

After dehydration and concentration, the mixture is extruded and dried to obtain the composite bass.

Post-processing

The finished bio-based leather is obtained by processing it according to the conventional microfiber leather process.

Advantages: High bio-based content and excellent degradability.

Challenge: The process is complex and production efficiency needs to be optimized.

Is Bio Leather Durable?

Yes, bio-leather can be very durable, but its strength depends on the specific type (mushroom, bacterial cellulose, etc.), and most importantly, the manufacturing and processing techniques used (such as “tanning” or cross-linking). So, not all bio-leathers have the same performance.

Durability largely depends on materials and craftsmanship

The strength of bio-leather is not inherent in the raw materials but is designed during the production process. For instance, the “tanning” process introduces cross-linking between molecules, which is crucial for enhancing strength and water resistance.

To give you a clear understanding of the performance, the following are the tensile strengths of different materials based on recent research (a key indicator of material strength) :

The key factors affecting durability

According to this study, there are three main factors determining the durability of bio-leather:

- Cross-linking (” tanning “) : This is the most crucial step. Studies have shown that treating mycelial sheets with crosslinking agents (such as synthetic glutaraldehyde or natural plant tannins) can significantly enhance tensile strength, improve enzyme resistance, and reduce water absorption rate.

- Material blending and plasticizing: Pure bacterial cellulose is strong but fragile. Research has found that blending natural oils (such as rapeseed oil) or polymers (such as acrylic soybean oil) is crucial for enhancing flexibility and elasticity while maintaining strength.

- Basic materials and growth: The selection of fungal strains, substrates and growth conditions affects the density and initial structure of the mycelial pad, which forms the basis of the final product.

Is Bio Leather Vegan?

Yes, bio-leather is classified as vegetarian because it is not made from animal skin. However, to ensure it meets your ethical and environmental standards, it is important to go beyond the “vegetarian” label and look at its specific ingredients and production process.

Core vegetarian principles

By definition, vegan leather refers to materials that are “100% pollution-free” (100% free of animal components and animal footprints) in both manufacturing and processing. Since bio-leathers are extracted from plants (such as mushrooms, pineapples or cacti), fungi or agricultural waste, they essentially meet this core criterion.

| Common Material | Common Binding/Coating Agents | Potential Concern |

| Apple Leather (AppleSkin) | Polyurethane (PU) | Derived from fossil fuels; affects biodegradability. |

| Pineapple Leather (Piñatex) | Polylactic Acid (PLA, corn-based) or PU coatings | PLA is biodegradable under industrial conditions; PU is not. |

| Mushroom Leather (Mycelium) | Varies; some require plastic-based polymers for durability. | Can compromise the material’s claim of being fully “plastic-free” or “compostable.” |

| Mango/Cactus Leather | Undisclosed “chemical substances” or bio-based polymers. | Lack of transparency makes it difficult to assess environmental impact. |

How to verify the vegan credentials of bio-leather?

- Check brand labelling: Look for explicit claims such as ‘100% vegan’, ‘animal-free’ or certifications (e.g., Cruelty-Free International approved vegan, Leaping Bunny).

- Review material lists: Avoid products containing hidden animal by-products (e.g., ‘beeswax coating,’ ‘gelatin adhesive’).

- Research lab-grown brands: For cell-cultured bio-leather, confirm the brand uses ‘animal-free growth media’ (e.g., Modern Meadow’s Zoa™ is certified vegan).

Why is bio-leather a core choice for vegan fashion?

Bio-leather was invented to address the ethical shortcomings of traditional leather (animal slaughter) and synthetic leather (petroleum-based, non-biodegradable). Its core mission aligns with vegan values:

- No animal harm or exploitation.

- Sustainable production (reducing food waste, lowering carbon footprint).

- Avoiding toxic chemicals (unlike traditional leather tanning).

As brands adopt entirely animal-free production processes, even the narrow controversies surrounding lab-grown bio-leather are subsiding.

Is Bio Leather Waterproof?

Yes, bio leather can be waterproof. Bio leather is not naturally waterproof, but most commercial products undergo waterproofing sufficient for everyday use (e.g., handbags, wallets, shoes).

Water Resistance by Bio Leather Type

| Type | Natural Water Resistance | With Coating | Notes |

| Mycelium leather (Mylo™) | Low | Moderate to high | Often coated with bio-PU for fashion use |

| Cactus leather (Desserto®) | Moderate (due to natural waxes in cactus) | High | One of the more water-resistant options |

| Piñatex® | Low | Moderate | Requires topcoat; not ideal for rain-heavy use |

| Apple/fruit waste leather | Low | Moderate | Can stiffen or discolor if soaked |

| Kombucha leather | Very low | Low (even with wax) | Mostly for art/design prototypes |

How Water Resistance Is Achieved

To make bio leather practical for bags, shoes, or upholstery, manufacturers often apply eco-friendly coatings, such as:

| Coating Type | Water Resistance | Biodegradability Impact |

| Plant-based waxes (e.g., candelilla, carnauba) | Moderate | ✅ High (still compostable) |

| Natural oils (e.g., linseed, jojoba) | Light to moderate | ✅ High |

| Bio-based polyurethanes (PU) | High | ❌ Reduces biodegradability |

| Aliphatic resins or acrylics (bio-sourced) | Good | ⚠️ Partially biodegradable |

| Silicone alternatives (bio-derived) | Very good | ⚠️ Varies |

Compared to Other Materials

| Material | Waterproof? | Notes |

| Animal leather (untreated) | ❌ No | Absorbs water; requires conditioning |

| Chrome-tanned leather | ⚠️ Slightly | More water-resistant but toxic |

| PU/PVC “vegan leather” | ✅ Yes | Plastic = inherently waterproof, but not eco-friendly |

| High-end bio leather (with coating) | ⚠️ Water-resistant | Not fully waterproof, but functional for daily use |

Key Factors Affecting the Water Resistance of Bio-based Leather

Raw Material Types:

- Plant-Based Materials: Plant-based bio-leathers such as pineapple leaf fibre (Piñatex) typically exhibit superior breathability and moisture absorption compared to conventional leather, though their strength and durability may be slightly inferior. Some products achieve enhanced water resistance through surface coating treatments.

- Microbial-based materials: Microbial-based bio-leathers, such as mushroom mycelium (Mylo), exhibit excellent biocompatibility and biodegradability. Certain products achieve customisable waterproofing through adjustments to fungal strains and culture media.

Production Processes:

- Surface treatment techniques: Utilising natural coatings (e.g., plant-based resins) enhances the abrasion resistance and waterproofing of bio-leather.

- Biocatalytic technology: Novel biocatalytic techniques improve production efficiency while optimising performance characteristics.

Post-treatment techniques:

- Waterproof chemical treatment: Applying waterproofing agents via spraying, or combining wet-field waterproofing with dry-field spraying, confers dynamic water resistance.

- Nanotechnology modification: Utilising nanotechnology enhances strength and abrasion resistance, potentially improving waterproofing properties.

Testing Methods for Bio-based Leather Waterproofing

- Water Bead Test: Place water droplets on the leather surface and observe whether they rapidly permeate. If droplets remain beaded without penetration, this indicates good waterproofing.

- Immersion Test: Submerge leather samples in water for a specified duration and observe whether water absorption or morphological changes occur. If the leather remains dry or only superficially damp, this demonstrates effective waterproofing.

- Spray Test: Simulate heavy rainfall by directing water jets onto the leather surface to assess surface water resistance. Compare the water mark pattern left on the leather after spraying with a standard reference card to determine its waterproof rating.

- Maeser Test Method: Place waterproof leather samples in a water tank, apply pressure, and subject them to repeated bending motions. Record the number of bends the leather can withstand before water penetration occurs. If over 15,000 bends are achieved without water penetration, this indicates excellent waterproof performance.

How to Enhance Water Resistance in bio-leather?

Which Treatment Methods Are effective?

Natural wax coatings (carnauba, rice bran) form a surface hydrophobic barrier (resistant to light rain)

Essential oil treatments (tea tree, eucalyptus) provide low to moderate antimicrobial and water-repellent properties

Bio-based polymer coatings seal pores while maintaining breathability

Nanotechnology treatments create superhydrophobic surfaces with maximum water repellency (though uncommon in consumer goods)

Practical Considerations for Consumers

1. Application-Specific Guidance

- Outdoor gear: Select products with high hydrostatic pressure ratings (>10,000mmH₂O), such as Anta’s ‘fluorine-free membrane’ technology.

- Automotive interiors: Silicone-based bio-leather is ideal, combining water resistance, abrasion resistance, and eco-friendliness.

- Everyday Items: Standard bio-based PU leather suffices for basic water resistance.

2. Limitations to be aware of

- Durability Concerns: Waterproof coatings on bio-based materials may degrade over time, requiring periodic maintenance.

- Extreme Environments: Waterproof performance may diminish in extreme cold or heat for certain bio-based leathers.

- Cleaning Precautions: Avoid harsh chemical cleaners to prevent damage to waterproof coatings.

Is Bio Leather Good for Making Bags?

Indeed, bio leather is an excellent material for crafting bags, as it combines the aesthetic appeal and durability of traditional leather with sustainability and ethical benefits. However, its suitability largely depends on the specific type and your brand positioning for the bags. While bio leather excels in sustainability and ethical credentials, its performance varies considerably and may not yet match the durability of high-quality traditional leather.

Advantages of Bio-Leather Bags

1. Environmental Sustainability

Compared to conventional leather, bio-leather significantly reduces environmental impact. Traditional leather production requires approximately 17,000 litres of water per hide and generates substantial wastewater containing harmful chemicals like chromium. In contrast, bio-leather made from agricultural waste—such as pineapple leaves, mushroom mycelium, or fruit residues—utilises renewable resources and reduces landfill waste. For instance, Piñatex requires 16 pineapple leaves to produce one square metre of leather, boasting a carbon footprint 90% lower than conventional leather.

2. Performance Characteristics

Many bioleder types offer performance advantages relevant to bags:

- Property: Bioleder Advantage: Traditional Leather Comparison

- Tensile strength: Some bioleders match or exceed traditional leather, varying by grade; full-grain being most durable

- Water resistance: Can be engineered for specific resistance; generally good but varies with surface treatment

- Design flexibility: Can be engineered for specific textures, colours, and thicknesses; limited by natural hide variations

- Consistency: Uniform quality without natural imperfections

Brands like MycoWorks (collaborating with Hermès) have developed mushroom-based leathers that match or exceed the strength of certain animal hides, demonstrating the potential for high-performance bio-leather bags.

Current Limitations and Considerations

1. Cost and Availability

Bio-leather typically commands a premium over synthetic alternatives, with production costs remaining roughly double those of conventional leather. This translates to higher retail prices for consumers. Availability also remains limited, though expanding rapidly as major brands adopt these materials.

2. Performance Variations

Not all bio-leathers are created equal. Some plant-based leathers may exhibit lower water resistance or durability compared to high-quality animal hides. It is crucial to examine the specific type of bio-leather and its intended application.

3. Care Requirements

Bio-leather bags typically necessitate special care:

- – Avoid prolonged exposure to direct sunlight

- – Clean plant-based materials using specialised detergents

- – Store in breathable bags rather than plastic packaging

- – May require more frequent conditioning than traditional leather

The Advantages and Disadvantages of Making Bags from Bio-Leather

| Aspect | Evidence Supporting Use in Bags | Evidence Raising Caution |

| Durability & Strength | – Luxury adoption: Brands like Hermès and Stella McCartney have used mushroom leather for handbags. – New innovations: A 2024 pineapple leaf fiber leather was reported to be significantly stronger than some other plant-based alternatives. | – Scientific testing: A 2022 independent study concluded that none of the tested alternative materials matched leather’s durability, particularly in tensile and tear resistance. |

| Water Resistance | – Natural coatings: Some bio leathers, like those made from leaves, are described as having a natural waterproof quality. – Engineered finishes: Technical research is developing high-performance, water-resistant bio-based polyurethane coatings for synthetic leather. | – Performance gap: The same 2022 study found alternatives scored “significantly lower” than leather in moisture absorption and breathability. |

| Sustainability & Ethics | – Core appeal: Made from renewable resources (mushrooms, pineapple leaves, cactus), reducing reliance on animal hides and plastics. – Consumer demand: Many brands are adopting these materials in response to demand for eco-friendly and cruelty-free products. | – “Greenwashing” concerns: Some “eco” leathers may contain high percentages of plastic (like polyurethane), and their full lifecycle environmental impact can be unclear. |

Types of Bio Leather for Bags

| Type | Source | Bag-Specific Advantages |

| Cactus Leather | Nopal cactus | Luxurious feel, extreme durability, water-resistant |

| Piñatex® | Pineapple leaves | Lightweight, flexible, ideal for structured bags |

| Mushroom/Mycelium | Fungal root structures | Biodegradable, molds well to 3D shapes |

| Apple Leather | Apple peels | Smooth texture, naturally antimicrobial |

| Corn/Wheat Leather | Grain byproducts | Strong, cost-effective, good for everyday bags |

| Cork Leather | Cork oak bark | Waterproof, extremely durable, natural texture |

When Bio-Leather Outperforms Traditional Leather

- Weight-sensitive designs: rucksacks, messenger bags

- Vegan/ethical brands: appealing to a growing niche market

- Environmentally conscious consumers: opt for carbon-neutral or carbon-negative options

- Summer bags: breathability prevents heat build-up

- Distinctive textures: natural patterns impossible to replicate in animal hides

When Traditional Leather May Be Superior

- Extreme weather conditions: some bio-leathers are unsuitable for heavy rain or snow

- Heavy-duty use: For bags requiring exceptional durability (e.g., tool kits)

- Antique/vintage aesthetics: Some traditional leathers develop distinctive patinas over decades

Tips for Selecting Bio-Leather Bags

- Check certifications: Look for the USDA Biopreferential label or TÜV OK biobased certification to verify bio-content claims. These certifications guarantee the material meets environmental standards.

- Understand the raw materials: Different bioleathers exhibit varying properties. Mushroom-based (mycelium) variants tend to be more durable, while fruit waste-based alternatives may offer distinctive textures but potentially lower resilience.

- Consider the brand’s commitment: Some labels utilise bioleather as part of genuine sustainability initiatives, whereas others may engage in “greenwashing”. Research the brand’s overall environmental practices.

- Evaluate based on intended use: For everyday bags, prioritise durability and water resistance. For fashion pieces, consider texture and aesthetic qualities.

Conclusion

Bio-leather emerges as an excellent material for bag manufacturing, offering commendable durability and strength alongside distinctive appearance and texture. Its inherent natural grain patterns and colour variations increasingly position it as a favoured choice for fashion, eco-conscious, and ethical consumption.

Design-wise, bio-leather can be embossed, dyed, and processed to achieve diverse textures and colours, meeting high-end brands’ pursuit of uniqueness and artistic flair.

If you run your own bag business or own a bag brand and wish to customise bio-leather bags, we welcome you to contact us to design and manufacture your bags together.