Banana leather is an innovative sustainable material, mainly processed from the waste of banana cultivation (such as stems and leaves), and it is an environmentally friendly alternative to animal leather and synthetic leather. It has been applied in fashion fields such as handbags, shoes and accessories, which not only reduces agricultural waste but also creates additional income for farmers. With the development of sustainable fashion, banana leather is gradually becoming a new choice for eco-friendly materials.

This guide will explore the characteristics of bananas, the features of banana leather, and whether it is good for manufacturing bags.

What is banana?

Bananas are a delicious, slender, typical yellow fruit that grow on large herbaceous plants in tropical regions. It is one of the most popular and widely consumed fruits in the world.

Botanically, bananas are classified as berries. This is because it develops from a single cell, is soft and succulent, and contains seeds (although they are small and undeveloped in commercial varieties).

- This plant is a herbaceous one: The banana plant is usually called the “banana tree”, but it is not a woody tree. It is the largest herbaceous flowering plant in the world. What looks like a tree trunk is actually a dense cluster of petioles (” pseudostems “).

- Edible part: The pulp is rich in carbohydrates (mainly sugar and starch).

- Nutritional value: Bananas are a good source of dietary fiber, potassium, manganese, vitamin B6 and vitamin C.

There are hundreds of varieties of bananas.

What is banana leather?

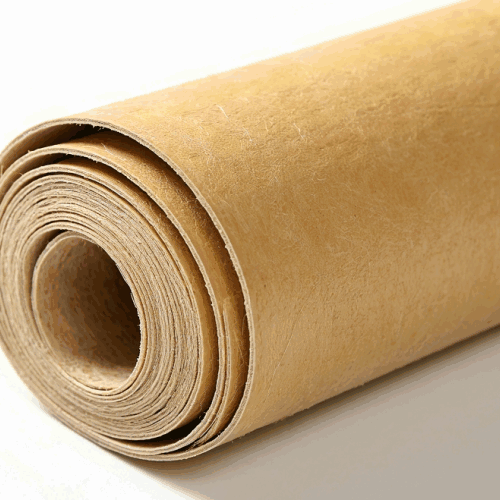

Banana leather is an innovative and sustainable leather material that can serve as an alternative to traditional animal leather. It is mainly made from banana crop waste, such as stems and leaves, which are transformed into durable plant leather. This material has attracted attention due to its environmental benefits and versatility in various applications.

Banana leather is used in fashion and accessories, such as handbags, wallets, shoes and clothes. Due to its texture and durability, it can also be used in special applications, such as grips of sports equipment (like golf clubs).

Banana leather is part of a broader movement in the fashion and design fields towards plant-based and vegan materials. Its development supports the principles of a circular economy by converting waste into valuable products.

The benefits of banana leather

- Environmental protection: Made from agricultural waste, it reduces landfill and discharge.

- Biodegradable: Unlike synthetic leather (such as PU or PVC), banana peels can decompose naturally.

- Ethical friendliness: No animal harm, in line with the trend of vegetarianism.

- Environmentally friendly and sustainable: Reduce agricultural waste, lower carbon emissions, and have strong biodegradability.

- Durable: Breathable and long-lasting, if processed well, it can be as strong and flexible as traditional leather.

- Customizable: Customizable textures and colors are available. Banana leather can be made to look and feel like traditional leather, and its natural variations endow each piece with a unique aesthetic.

- Good physical properties: Its tear strength, flexibility, appearance and touch are all comparable to those of animal leather. The thickness is between 0.7 and 0.9 millimeters. It is also waterproof, mold-proof, ultra-light and biodegradable.

Challenge of banana leather

- Large-scale production: Issues such as equipment compatibility and process stability need to be addressed (such as the impact of temperature control on material toughness).

- Cost and market: The initial R&D cost is high, and it is necessary to reduce the cost through commercial cooperation (such as cooperation with luxury goods groups).

- Consumer awareness: It is necessary to popularize the concept of banana leather and break the traditional cognitive inertia of leather.

Is banana good for making leather?

Yes, bananas are indeed an excellent material for making leather, especially as a sustainable and innovative alternative to traditional animal leather.

Bananas are an excellent leather material because they are sustainable, durable and have a positive socio-economic impact. It meets the growing demand for environmental protection and ethical fashion, although challenges such as material mixing and cost still exist. With the advancement of innovation, banana leather is expected to become the mainstream alternative in various industries.

Why bananas are good for making leather?

1. Environmental benefits

- Reduce waste: Banana leather is usually made from agricultural waste such as banana stems, leaves and discarded fruits, otherwise these wastes would be disposed of, causing environmental pollution.

- Lower resource consumption: Compared with animal leather, banana leather uses 95% less water in production and reduces carbon emissions by 90%. It also avoids the pollution produced in the traditional tanning process.

- Biodegradability: Many banana leather products are biodegradable or compostable, especially those made from natural fibers without synthetic additives, reducing their long-term impact on the environment.

- Sustainable raw material: Banana plants are harvested only once – after fruiting, the plants are cut down, leaving tons of remaining stems. These false stems are rich in strong fibrous materials and are the perfect choice for textile and leather substitutes. Make use of agricultural waste, otherwise it will be left idle or rot.

- Environmentally friendly production: Unlike synthetic leather (PVC, PU) that uses toxic chemicals and is not biodegradable, banana leather requires minimal demanding processing. Most production methods use water, natural enzymes and plant dyes, reducing the carbon footprint. Banana leather is 100% plant-based and free of toxic chemicals.

2 Material properties and durability

- High fiber content: The fibers in banana stems are firm, durable and flexible. Processed materials can make their appearance, feel and performance like animal leather (especially for bags, wallets, shoes, etc.).

- Strength and flexibility: Banana fiber is renowned for its strength and durability, making it suitable for manufacturing products such as handbags, shoes, and accessories. For instance, the materials of Banofi leather have been certified for durability and meet the industry standards for non-toxic leather.

- Versatility: Banana leather can be processed into various textures, such as a wrinkled feel, and can also be made waterproof and flexible. It is also lightweight and breathable, making it an ideal material for making clothing and accessories.

- Application: It is used in fashion (such as handbags, wallets, shoes, jackets), sports equipment (such as golf club grips), and even car interiors.

3 Economic and social impacts

- Farmers’ income: Purchasing banana waste provides farmers with additional income by buying crop waste to support low-income farmers.

- Creating job opportunities: Projects for banana fiber production can create job opportunities for communities, such as in the Philippines where banana cultivation is prevalent.

4 Challenges and Considerations

- Durability and synthetic mixtures: Some banana leather products may blend natural fibers with synthetic materials (such as polyurethane) to enhance strength and texture, which may affect biodegradability. Consumers should read the product manual and choose completely natural products.

- Cost and availability: Although banana leather is constantly evolving, it is still on the rise and may be more expensive than synthetic leather, although it is usually more affordable than animal leather.

Bananas have unique advantages that make them suitable for leather production, which stem from their biological structure and availability.

Considerations:

| Pros | Cons |

| Sustainable & biodegradable | May require blending with other materials for strength |

| Cruelty-free | Not yet as durable or flexible as top-grade animal leather |

| Uses agricultural waste | Production process still being scaled |

Banana leather VS. Animal leather

| Category | Banana Stem/Pseudostem Leather | Traditional Animal Leather |

| Raw Material | Plant fibers (stems/pseudostems) | Animal hides (cattle, sheep, etc.) |

| Environmental Impact | Low carbon emissions, biodegradable | High pollution (chromium salts, formaldehyde) |

| Resource Consumption | Utilizes agricultural waste | Relies on livestock farming |

| Performance | Breathable, durable, customizable | Flexible, wear-resistant but ethically controversial |

Is banana leather waterproof?

Yes, banana leather can be waterproof, but not completely. This depends on their processing methods, and to a large extent, on the specific processing techniques and materials used in their production.

- Material properties: The main component of banana leather is plant fiber, and this material itself does not have natural waterproof performance.

- Processing and handling: However, the quality of the materials also depends on the “effort” made later in life. If banana leather undergoes special waterproof treatment during the production process, such as applying a waterproof coating or finish (like wax, plant-based resin or synthetic layer), or other waterproof techniques, its waterproof performance will be greatly enhanced! It’s just like putting a “raincoat” on a piece of clothing, making it hard for rainwater to seep in.

- Actual use: But then again, even if the banana leather has undergone waterproof treatment, it still cannot guarantee that it can “swim freely” in water without any obstacles! After all, the waterproof performance is limited. Prolonged soaking or vigorous rubbing may still affect its waterproof effect.

Compare with other materials

| Material Type | Water-Resistant? | Waterproof? | Notes |

| Banana Leather (Bananatex) | Only when coated (e.g., beeswax) | Yes, if coated properly | Requires treatment to become waterproof |

| Natural Leather (untreated) | No | No | Porous and absorbs water |

| Natural Leather (treated/finished) | Yes (e.g., semi-aniline) | Some specialty types | Niagara-grade “Torino” tested waterproof Garrett Leather |

| PU Leather | Yes | No | Light rain safe; flexible but prone to cracking over time |

| PVC Leather | Yes | Yes | Durable waterproof, but less breathable and environmentally less friendly |

| Plant-Based Leathers | Varies (coated may resist) | No | Coatings add resistance; natural fiber versions usually not waterproof |

| Waterproof Technical Fabrics | Yes | Yes | High-performance, tested for true waterproofing |

Is banana leather durable?

Yes. Banana leather have moderate to high durability. The expected lifespan of products made from banana leather is usually 3 to 5 years. Although its lifespan may not be as long as that of top-quality animal leather, it offers a sustainable and sturdy alternative to daily necessities. Its durability can be maximized through proper care and by choosing products from well-known brands that use advanced processing methods. The durability of banana leather depends on several factors, including manufacturing processes, treatment methods and maintenance conditions.

Durability factors of banana leather:

- Natural fiber strength: Fibers derived from the pseudostem of the banana plant possess natural strength and firmness, providing a fundamental strength for the material.

- Processing and coating: To transform fibers into materials similar to leather, natural gum, adhesives, and sometimes protective coatings (such as bio-based resins or waxes) are usually used for processing. These treatments significantly enhanced its wear resistance, tear resistance and water resistance.

Type of Banana Leather

There are two main types:

A. Fiber-based banana leather (e.g. Bananatex):

- Made from Abacá fibers (a type of banana plant native to the Philippines).

- Woven into a fabric, sometimes compared to canvas or heavy-duty hemp.

- Durable and strong, used in backpacks, shoes, and accessories.

B. Pulp-based banana leather (e.g., from banana peels or waste):

- Formed more like a sheet or film, similar to early bio-leathers.

- Less durable: Can crack, degrade faster, or absorb moisture if untreated.

- Suitable for prototypes or experimental fashion, not heavy wear.

Durability Characteristics of Bananatex (as benchmark):

| Property | Performance |

| Tensile strength | High (similar to tough natural fibers) |

| Abrasion resistance | Good for bags, moderate for shoes |

| Biodegradability | Yes — breaks down safely over time |

| UV resistance | Moderate (may fade over long exposure) |

| Water resistance | Yes, if wax-coated |

| Tear strength | Good for fabric use |

Compared to Other Materials:

| Material | Durability (1–5) | Notes |

| Bananatex | ⭐⭐⭐⭐☆ (4/5) | Comparable to canvas or hemp fabric |

| Traditional leather | ⭐⭐⭐⭐⭐ (5/5) | Tough, ages well, but less eco-friendly |

| PU leather | ⭐⭐⭐☆☆ (3/5) | Less durable, cracks with time |

| Pinatex (pineapple) | ⭐⭐⭐☆☆ (3/5) | Durable when coated, weaker raw |

| PVC leather | ⭐⭐⭐⭐☆ (4/5) | Very durable, but stiff and not breathable |

Is banana leather good for making bag?

Yes, banana leather are an excellent material for manufacturing bags, offering a unique combination of sustainability, durability and aesthetic appeal. Especially when our goal is to create a product that is both sustainable and durable for daily use. Its suitability stems from the combination of its physical properties and environmental benefits.

Feasibility Analysis of Making Bags with Banana Leather

1. Characteristics of banana material

- Environmentally friendly and renewable: The biggest highlight of banana leather is its environmental friendliness! It is made from the discarded parts of banana plants (such as stems and leaves), which are degradable and renewable. Using it makes me feel so comfortable, as if I have also contributed to the Earth!

- Unique appearance: The appearance of banana leather is also very distinctive. It has a natural texture and color, giving people a simple yet fashionable feeling. If you make it into a bag, it will definitely make you stand out in the crowd and become the focus!

- Soft texture: The texture of banana leather is relatively soft and not as stiff as traditional leather. This is both its advantage and disadvantage. The advantage is that it feels comfortable to the touch, while the disadvantage is that it may not be easy to maintain the shape of the bag.

2. The applicability of banana leather bags

- Light-load use: If you only need a small bag for daily travel, such as a handbag or crossbody bag, to hold small items like a mobile phone, wallet, and keys, then banana leather is definitely a good choice. It is lightweight and fashionable, fully meeting your needs.

- Fashion matching: The unique appearance of banana leather has also made it a favorite in the fashion world. Whether paired with casual or formal wear, it can be easily handled, adding a touch of brightness to your overall look.

- Creative Customization: Banana leather is also very easy to be creatively customized! You can add various decorative elements to your bag according to your own preferences, such as embroidery, patchwork, metal accessories, etc., to make your bag more unique.

Limitations to Consider

| Limitation | Details |

| Rigidity | Slightly stiffer than animal leather; may not suit slouchy or soft bag styles. |

| Edge Finishing | Raw edges can fray unless sealed or hemmed. |

| Weather Sensitivity | Needs re-coating (e.g., wax) over time to maintain water resistance. |

| Not Stretchy | No elasticity — seams must be well-designed to avoid stress points. |

Which types of bags are not suitable for being made of banana leather?

Although banana leather is suitable for most daily bags, it has limitations in high-wear or extreme usage situations:

- Heavy-duty bags: They cannot replace polyester or thick cowhide hiking backpacks, work tool bags, or large travel coarse canvas bags. Its tear strength is lower than that of polyester. Sharp objects (such as rocks in a backpack) may Pierce it, and it cannot bear the weight of heavy equipment (such as laptops and books in a student’s daily backpack).

- Long-term outdoor exposure: It performs poorly in extreme weather conditions (heavy rain for more than 8 hours, low temperature). Unlike natural rubber (waterproof) or treated polyester (resistant to heavy rain), heavy rain may seep into the banana leather. Although it won’t harden like rubber, it may take longer to dry.

- Large-capacity bags: For oversized handbags (for example, beach bags for towels and snacks), their fiber structure may slightly stretch under long-term heavy loads (though less than PU). It is more suitable for medium and small-capacity bags (up to 10L).

Comparison with Common Bag Materials

To further clarify its suitability, here’s a quick comparison of banana leather with 4 popular bag materials:

| Bag Material | Suitable Bag Types | Durability (Daily Use) | Practicality (Water/Weight) | Eco-Friendliness |

| Banana Leather | Crossbody bags, wallets, clutches, small satchels, casual totes (≤10L) | 2–3 years | Repels light rain; lightweight | Excellent (biodegradable, low waste) |

| Traditional Cowhide | Luxury satchels, leather totes | 5–10 years | Absorbs water (stiffens); heavy | Poor (toxic tanning, non-biodegradable) |

| PU Synthetic Leather | Budget crossbody bags, fashion totes | 1–1.5 years | Repels light rain; lightweight | Poor (non-biodegradable, microplastics) |

| Cotton Canvas | Casual tote bags, beach bags | 1 year | Soaks through water; lightweight | Moderate (natural fiber but high water/energy use for washing) |

Where to custom banana leather bag?

If you want to customize a banana leather bag, you can look for a handicraft market near your location. There are usually many studios of independent designers and artisans there, and they may offer customization services for banana leather bags.

You can also visit some leather goods customization stores for consultation. Although traditional leather goods customization stores may mainly produce bags made of animal leather, there are also some stores willing to try new materials, such as banana leather.

If you are running your own leather bag business and want to customize a large number of banana leather bags, you can look for a leather bag manufacturer, such as Leather Bag Factory in China.

Leather Bag Factory: This Chinese bag manufacturer offers OEM services and produces various bags (such as handbags, backpacks and travel bags). We accept custom designs and samples.

Key considerations for customizing banana leather bags

- Material authenticity: Ensure that the “banana leather” is truly derived from the banana plant and is not merely a style name. Discuss the properties of the material, such as water resistance and durability.

- Custom workflow: Most custom orders involve steps such as consultation, design collaboration, sampling, and production.

- Minimum Order Quantity (MOQ) : Manufacturers like Guangzhou Leather Bag Factory may require a minimum order quantity for custom orders, while artisans may handle individual pieces flexibly.

- Delivery time: Custom bags take time (for example, a Thai banana leather bag will take 75 days to ship). The corresponding plan.

- Cost: Banana leather products, especially those made by hand, may be more expensive due to the sustainability of materials and labor.

Conclusion

Banana leather is an excellent material for making bags and has been widely used in fashion, casual wear and daily handbags. It offers a good balance of sustainability, durability and aesthetics, making it the first choice for brands and consumers who want to make ethical and eco-friendly purchases.

If you are looking for a manufacturer that can customize banana leather bags, please feel free to contact Leather Bag Factory. We are a bag manufacturer based in Guangzhou, China, and have been dedicated to customizing leather goods for 19 years.